FONT

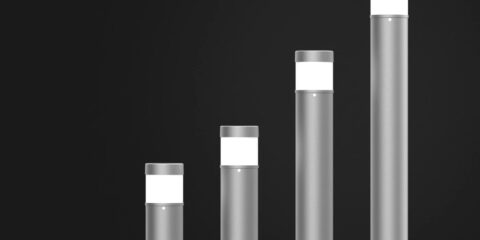

IP65 IK08. Originaalne kvaliteetlahendus nõudlikule kliendile.

Die-cast body and flange manufactured in aluminium alloy EN 44300 with very low copper content. Painted steel pole. Glass diffuser. Subjected to galvanic anodizing treatment divided into distinct phases: mechanical satin finishing, surface degreasing, anodic oxidation and final sealing. The product is painted following a continuous two step paint process (epoxy-based primer + polyester-based colour finish), which allows to generate a single thick protective coating which then generates aprotective barrier against atmospheric agents and UV rays. Before fixing the diffuser on the Platek products a Pre-treatment using an atmospheric pressure plasma process is carried out on the surface. The process activates the ionic load on the surface exactly where it is needed, thus promoting the best silicone grip possible and removing any residual release of agents for a longer lasting seal. The next steps are the coating of silicone and the assembly of the diffuser on the lighting fixture, with an automated process to guarantee the perfect sealing of the lamp.